Post by Admin on Jan 17, 2018 11:22:30 GMT -6

Summer Diesel or what is referred to a #2 Diesel is perfect for summertime use but as the temperatures begin to fall it can cause issues for Diesel Engine Owners. #2 Diesel contains paraffin and as the temperatures drops the paraffin begins to solidify. At 32° F the paraffin wax begins to crystalize and will start making the diesel fuel look cloudy. When #2 Diesel reaches the 10° to 15° F temperature range it will start the formation of "Gelling" or "Waxing" and start plugging the Fuel Filters and Lines.

Winter Diesel is a Blend of #2 and #1 Diesel Fuel that lowers the viscosity and gel point of Winter Diesel Fuel or can be #2 Diesel with Anti-Gel Additives. As seen here on the label at a local fuel station they start selling Winter Diesel Blend November 1 through March 31.

But what happens if you tank is already full of Summer Diesel or Unsure of the Protection Level of the Fuel in your Tank. That is where Fuel Treatments are recommended. Products like AGCO Parts Total Power Best Antigel is not only a Anti-Gel but Fuel Conditioner too. It helps lower the gel point to provide trouble free operation in the winter months too. It is recommended to treat fuel when Fuel Temperature is +40°F or Above to allow the product to mix correctly (Homogenize) and chemically do its job.

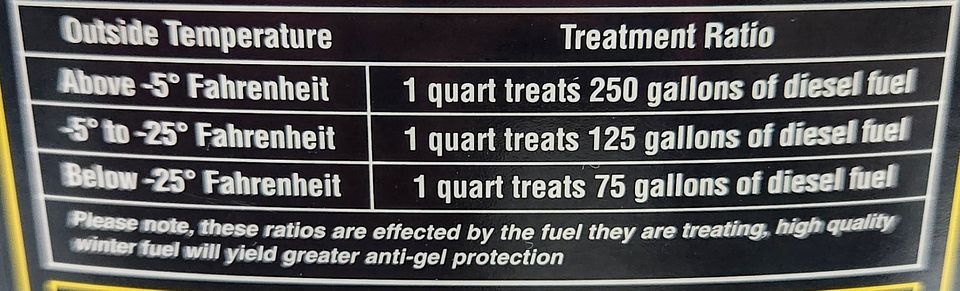

AGCO Parts Total Power Offers 3 Levels of Protection for Temperatures above -5°F one Quart will Treat 250 Gallons of Fuel/ From -5°F to -25°F one Quart will treat 125 Gallons of Fuel and for Extreme Temperatures below -25°F One Quart will treat 75 Gallons of Fuel. Plus it's compatible with your Engines High Pressure Direct Injection System and Engine Exhaust Emissions Systems. Dosing Rates vary by Temperature and need to compare and blend rates to match the lowest temperatures you may encounter. AGCO Parts are the Genuine Parts of Massey Ferguson and Guaranteed to Protect Your Investment

Ratios are effected by the Fuel they are Treating. High Quality Winter Fuel will Yield Greater Anti-Gel Protection.

Bio-Diesel brings in another Issue as it contains Oils and the Cloud Point and Pour Point typically happens at higher temperatures than Petroleum Fuels. BioDiesel often require special Anti-Gel Products to Treat these Oily/Fatty Fuels. Here is more information: farm-energy.extension.org/biodiesel-cloud-point-and-cold-weather-issues/

Fuel Tip:

When Treating your Bulk Tank with AntiGel or in Cold Weather insert the nozzle into the fill hole and recirculate the Fuel back into the tank. This will prevent adding the wax flakes getting into the vehicle or tractor and help circulate the fuel before filling. This would be a good tip even in the summer to do before you fill. Cheaper and Easier to change Tank Filters than Tractor Filters and will save you trouble in the winter with Fuel Gelling.

Fuel Blending Recommendation:

Temperature Above -4°C (+39°F) 100% Grade 2-D & 0% Grade 1-D

Temperature Down to -4°C to -21°C (+39°F to -5°F) 50% Grade 2-D & 50% Grade 1-D

Temperature Below -21°C (-5°F) 0% Grade 2-D & 100% Grade 1-D

In Northern Climates like Northern Border States and Canada below 39°F straight Number 1 Diesel Fuel is Recommended. It may cost more but #1 Diesel Fuel does not contain Paraffins/Waxes like #2 Diesel Fuel. has a lower pour point so it stays in flowable product to lower temperatures and it combusts easier. Good Information on #1 versus #2 Diesel: www.papekenworth.com/blog/diesel-1-vs-diesel-2-is-premium-worth-it#:~:text=Diesel%20%231%20is%20also%20known,blended%20for%20local%20weather%20conditions.&text=Diesel%20%232%20costs%20less%20at%20the%20pump.

More Information on #1 versus #2 Diesel: kendrickoil.com/understanding-differences-diesel-fuel-grades/

Now available from AGCO Parts is D-Max Winterthaw Emergency Fuel Treatment...if you get caught by cold temperatures and need to get your fuel ungelled the only solution is an Emergency Fuel Treatment that can dissolve the Gelling. D-Max Winterthaw not only does this but also protects your tractors and fuel system as they are approved for use by AGCO Warranty & Service Department. Be careful what you put into your fuel it can have negative effects on High Pressure Common Rail System that can run up to 40,000PDI and Exhaust Emission Systems too.

Even Your Massey Ferguson Dealer gets caught with Gelled Fuel...But AGCO Parts to the Rescue!

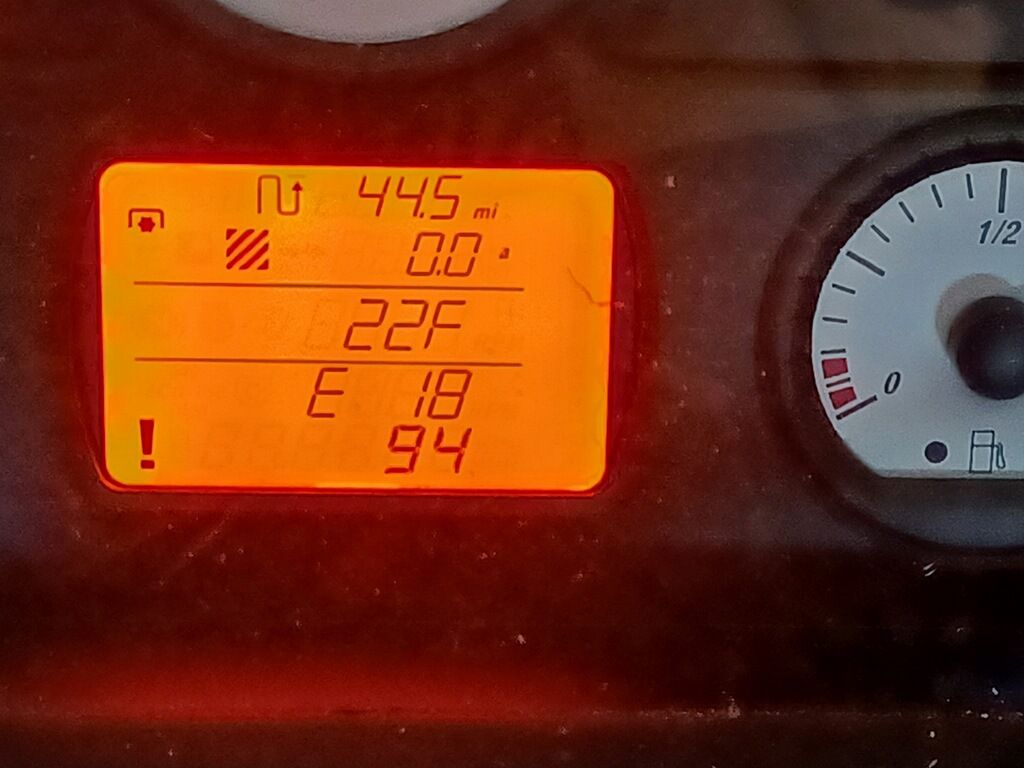

Fuel Filters are prone to get slimed, plugged or gelled with Gelled Fuels. Error Code E94 is Low Fuel Pressure and caused by Gelled Fuel blocking flow of Fuel or Dirty Fuel Filters from Fuel Contaminants like dirty, grime, etc which can also slow fuel flow and restrict fuel as it begins to gel. Once a Filter gets plugged it needs to be replaced. It's hard to remove the waxing or gelling in a filter and get the proper flow through it to run your Engine.